| Sign In | Join Free | My fnxradio.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My fnxradio.com |

|

Brand Name : Unite Steel

Model Number : Dia: 10-350mmm

Certification : ISO/MTC/BV/SGS

Place of Origin : China

MOQ : MOQ :2-3 Ton

Price : USD 600-900 per Ton

Payment Terms : L/C, D/A, D/P, T/T

Supply Ability : 3000 Ton per Month

Delivery Time : Within 15-45 days

Packaging Details : Stanard seaworthy packing or as your request .

Product name : SAE 3310 Hot Rolled Steel Bar , Modified Alloy Steel Round Bars , Delivery condtion QT

Material grade : SAE 3310

Delievry condition : Annealed/hot rolled/cold drawn/quenched & tempered

Surface : Black/machined/peeled/polished/turned

Shape : Round section

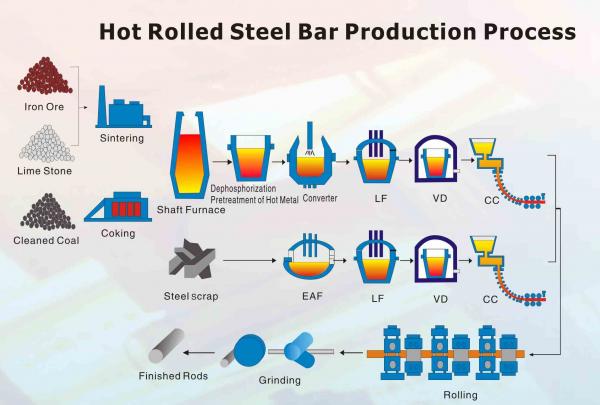

Process : EAF+LF+VOD+Rolled+Heat Treatment(optional)

Ultrasonic inspection : 100% ultrasonic inspection for any inperfections or based on the customer's requirement

Certificate : ISO/MTC/BV/SGS

SAE 3310 Hot Rolled Steel Bar , Modified Alloy Steel Round Bars , Delivery condtion QT

Steel group: Case hardening steel

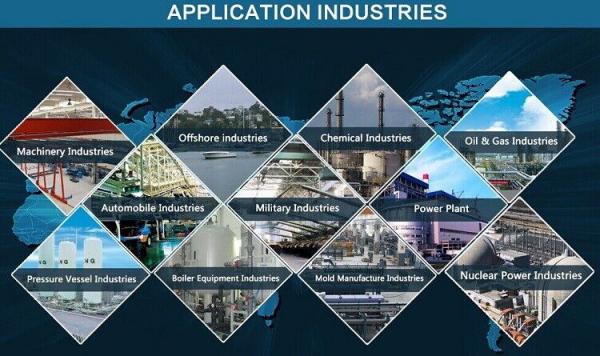

Application: Highly stressed large sized components for aircraft and truck construction, and for general engineering purposes, e.g. gear wheels, cranks hafts, heavy-duty gear shafts.

Features: 20Cr2Ni4 is high intension of alloy cementation steel ,has excellent comprehensive mechanical property. It's hardenability and obdurability higher than 12CrNi3. It's excellent forgeability.

Related specifications:

| Germany | W.Nr 1.5752 DIN 14NiCr14 |

| Great Britain | BS970 – Part 3 – 1991 655 M13 |

| BS970 | 1955 EN36A |

| GOST | G55H13, G55M13 |

| Japan | JIS G 4052 SNC815H |

| JIS | G 4102 SNC815 |

| U.S.A. | SAE 3310 9310 |

| AISI | E 3310 E9310 |

| France | 12NC15, 14NC12 |

| Australia | AS 1444-2007 – X3312/X3312H |

| UNS | G33106/G93106 |

Color of end: SIGNAL RED END

Quality Standard:

EN 10277 - 4 : 2008 Bright steel products. Technical delivery conditions. Case hardening steels

EN 10084 : 2008 Case hardening steels. Technical delivery conditions

Chemical Composition(%):

| C | Si | Mn | Cr | S | P | Ni |

| 0.17-0.23 | 0.17-0.23 | 0.30-0.60 | 1.25-1.65 | 0.04max | 0.04max | 3.25-3.65 |

Process: EAF+LF+VOD+Rolled+Heat Treatment(optional)

SIZE RANGE:

Round:

Hot Rolled: 10mm –350mm

SURFACE FINISHES:

Black, Peeled (K12), Cold Drawn, Turned & Polished (H10, H11), Precision Ground (H9, H8)

Ultrasonic test: According to SEP 1921-84 3C/c

Range of application and heat treatment :

Cementation steel : gear wheels , crankshafts , gear components

Hardening : 830 - 850 °C (oil) Soft annealing : 620 - 650 °C Normalising : 830 - 860 °C

Certificate of Quality: issued in English, in addition the normal terms, production process, the mechanical property (yield strength, tensile strength, elongation and hardness), forged ratio, UT test result, Grain size, heat treatment methods and the sample of is shown on the Certificate of Quality.

Marking: Heat No. will be cold stamped and Steel grade, diameter (mm), length (mm), and the manufacturer LOGO and weight (kg) is painted

|

|

SAE 3310 Round Steel Bar Hot Rolled Technical 0.17%-0.23% Chemical Composition Images |